- Rye Malt Guide – How to Use This Malt for Distinctive Homebrews - November 24, 2022

- Aromatic Malt Guide – Why I Use This Malt in My Homebrew Recipes - November 19, 2022

- Willamette Hops Guide – Why I’m a Fan of This Classic American Hop - November 9, 2022

Cold crashing is a process that is often used to enhance the clarity of beer and other homebrews. In my cold crashing beer explained guide, I will take you through the cold crashing method so you know how to do this yourself.

I’ll also look at the pros and cons of cold crashing and list some products required to carry out this process. Towards the end, I’ll answer some frequent questions that people often ask.

First, let’s take a deeper dive into cold crashing and why it is done.

What Is Cold Crashing Beer?

You might have come across the term ‘cold crashing,’ but what actually is this process, and why do brewers use it? Many people ask me, ‘how do you get crystal clear beer?’, and this is exactly what cold crashing is designed to do.

Cold crashing is a method to enhance the overall clarity of the beer. It is carried out at the end of the fermentation stage and before you bottle the brew. Not every beer, lager, or ale, will require cold crashing as some will have a clear complexion without this method. However, many brew types do require cold crashing if you want a clean and crisp finish.

The process involves storing the beer at a very low temperature, and I will take you through the steps for this in the next section.

Certain brew types will require a more extended cold crashing period than others. For example, light-colored beers such as those that use flocculent yeast strains may only require a day or two of cold crashing. Other beers, such as those from Bavaria and Belgium, may need cold crashing for a few weeks to create a clean, crisp, and light finish.

How to Cold Crash Beer

If you do want to cold crash your homebrews, then there are certain steps that you need to follow. Before we get into the actual process, there are some items you’ll need first.

What You Need

You don’t need anything particularly complicated to cold crash beer; however, a few items are required for this process.

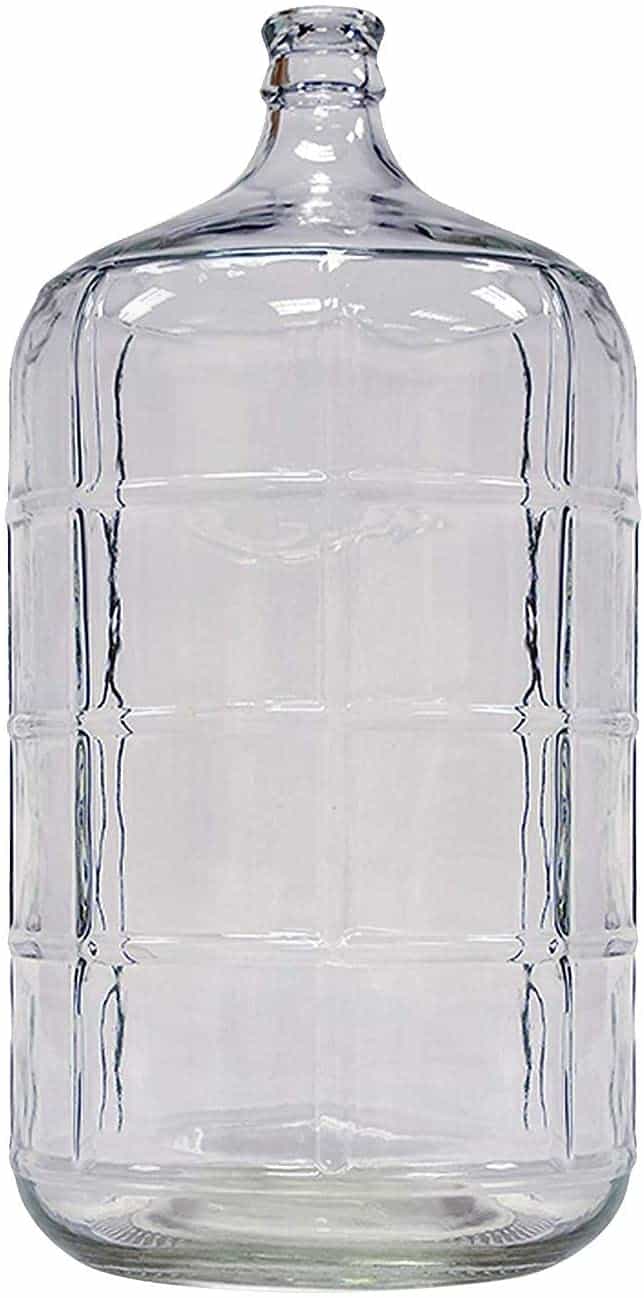

Carboy

The first item you need is something actually to hold the beer in for cold crashing. A carboy is a perfect option for this as they are very cost-effective and available in many different sizes. The carboy doesn’t even need to be airtight (it just needs a relatively secure seal), but it does need to be sanitized and clean.

You can use other storage containers for this purpose, but I have found that a carboy works well.

Refrigerator

Before you go out and decide to buy a fancy new fridge that costs a lot of money, your existing fridge is fine.

Many people cool down the temperature of their brew by simply leaving it outside in colder weather or in an uninsulated garage where the temperature is low. A fridge will give the most effective results as the temperature can be controlled. I often see people using a freezer for this purpose; however, you need to be careful around temperature regulation as you don’t want the beer to freeze.

Digital Temperature Controller

Another item you might need is a digital temperature controller, which will come in handy if you are using a freezer.

A digital temperature control lets you regulate the temperature to ensure your brew doesn’t cool down or heat up too much.

The Cold Crashing Process

So, now you know why cold crashing beer can be an essential step and what equipment you need to do it; let’s go through the process.

Step one

Before you do anything, you need to ensure that the initial or secondary fermentation process is complete. You can use a hydrometer to measure the gravity.

Related: Hydrometer vs Refractometer: What’s the Difference?

Step two

Once you are happy that the fermentation stage is complete, you need to transfer your brew into a sanitized and clean container. A carboy is perfect for this purpose or if you have a specific fermentation vessel.

Step three

Move your brew to the fridge, or you can even use the great outdoors if you live in a cold climate. The temperature you want the beer to reach is 34°F (1°C); this is generally the lowest temperature you can get in a fridge. If you are using a freezer, you’ll want a temperature controller to ensure it doesn’t freeze.

Don’t worry too much if you can’t get to 34°F, as long as it is within the 34° – 45°F range, the beer will still cold crash.

Step four

Leave the beer at this temperature for as long as required. This will depend on the type of brew you are making, as some will only take a couple of days while others can take weeks.

Step five

Once the beer looks clear, you can move it into bottles. Don’t worry if it isn’t completely clear, as this is not what you are aiming for; even if some yeast is left, this will help the carbonation process.

Pros and Cons of Cold Crashing

Cold crashing is viewed as essential for many brewers; however, some people don’t really bother with this process. I have come up with some concise pros and cons of cold crashing homebrews.

Pros

- Cold crashing improves the clarity and clearness of beer

- It is a fairly simple procedure to follow

- You don’t need much additional equipment

- It helps with the racking process

Cons

- You need to be careful with the temperature control

- Cold crashing will extend the brewing process

- If not done correctly, the flavor can be impacted

Product Recommendations

One of the advantages of cold crashing is that you don’t need many fancy pieces of equipment to carry out the process. Some products will help with cold crashing, and these are the items I recommend.

Inkbird All-Purpose Digital Temperature Controller

The Inkbird All-Purpose Digital Temperature Controller is a user-friendly item that allows you to regulate your fridge or freezer temperature better.

Achieving a temperature of around 34°F (1°C) is essential for cold crashing beer, and with this device, you can do just that. This digital temperature controller features both Fahrenheit and Celcius temperatures, and it also has an alarm function. You can set a temperature range, and if it goes over or above this amount, the alarm will alert you.

You would think that this device will cost a lot of money; however, it is available at a very low cost but can have a massive impact on cold crashing beer.

E.C. Kraus 6 gal Glass Carboy

You can use various storage options for your brew before starting the cold crashing process, but I have found using a carboy the best solution.

The great thing is that it isn’t costly and it is easy to clean and maintain. The E.C. Kraus 6 gal Glass Carboy is my pick as it ticks both of these boxes. Alongside being available at a low cost, it also has an impressive 6-gallon capacity, perfect for ensuring you get a large batch of your next homebrew creation.

Frequently Asked Questions about Cold Crashing Beer

Question: Do I need to cold crash my homebrew?

Answer: Not always. Some darker brews, such as stout, don’t require cold crashing; however, cold crashing will improve color and enhance the flavor if you make lighter colored beers and ales.

Question: How long should I cold crash my beer?

Answer: How long you need to cold crash the beer depends on the type of beer you are making. Some will be finished after a few days, although others can take up to three weeks.

Question: Does cold crashing affect flavor?

Answer: Cold crashing can have an impact on flavor and aroma if it isn’t carried out correctly. However, if you follow all the steps properly and ensure that the risk of oxygen getting into the vessel is minimized, the flavor and aroma of your beers and ales should be preserved.

Question: Is it difficult to cold crash beer?

Answer: Not really. In terms of homebrewing science, cold crashing is often one of the more straightforward processes to follow. You do need to ensure that the temperature is kept consistent for cold crashing and that you leave the beer long enough to remove yeast.

Question: Is fermenting necessary to make beer?

Answer: Yes. If you are making non-alcoholic beer then fermenting isn’t necessary, but for alcoholic lagers, ales, and other brews, the fermentation stage is vital.

Question: Is fermentation temperature important?

Answer: Cold crashing beer is done after fermentation is complete; however, the fermentation temperature is very important. Typically, the fermentation temperature for lager should be 40–54 °F (4–12 ºC) while for ale it is 55–70 °F (13–21 ºC).

Question: What is priming sugar for beer?

Answer: Priming sugar dissolves quicker than regular sugar and is often used in the fermentation process to create high-quality brews. This type of sugar is 100% fermentable and is great for conditioning and carbonating.

Question: Do I need a fridge to cold crash beer?

Answer: You don’t. I recommend using a fridge to provide a more consistent temperature and is more effective at cold crashing. Although, you can simply leave the beer in an uninsulated garage, basement, or you can even leave it outside if the temperature is cold enough but doesn’t freeze.

Question: What temperature do I cold crash beer at?

Answer: The temperature you want the beer to reach is 34°F (1°C), although if it is within the 34° – 45°F range, the beer will still cold crash, but it can take longer.

Conclusion

Cold crashing beer is an important stage in improving clarity and removing yeast from beer, and this is a step that many brewers carry out before bottling.

While some people don’t bother with cold crashing, it can help to improve the color and potentially the overall flavor and consistency of your homebrews. While you don’t need any significant equipment to carry out the cold crashing process, some items I do recommend that you buy are:

- Inkbird All-Purpose Digital Temperature Controller – this will help to regulate the temperature to ensure consistency when cold crashing beer

- E.C. Kraus 6 gal Glass Carboy – this carboy is perfect for storing your brew in a clean and safe environment